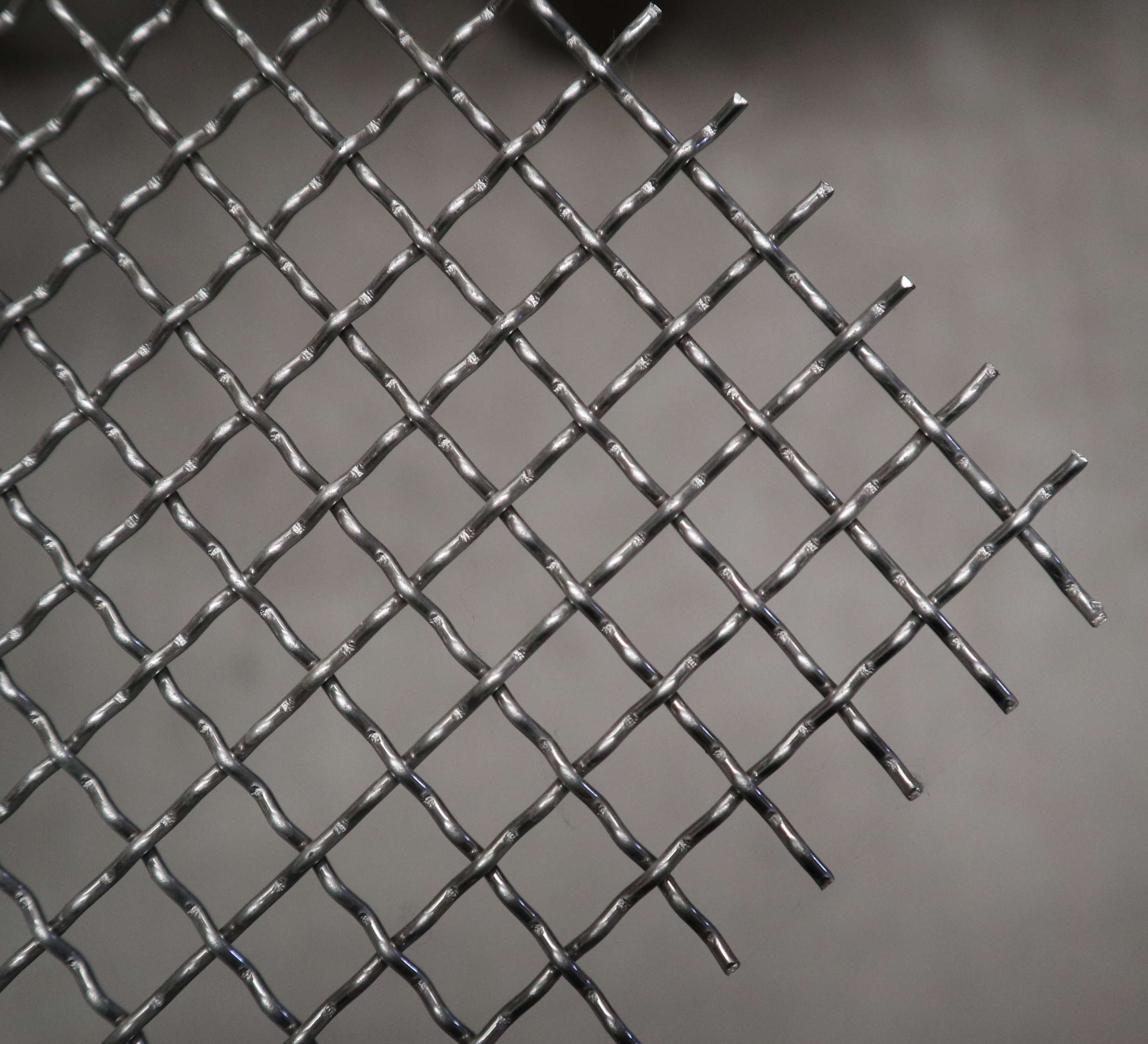

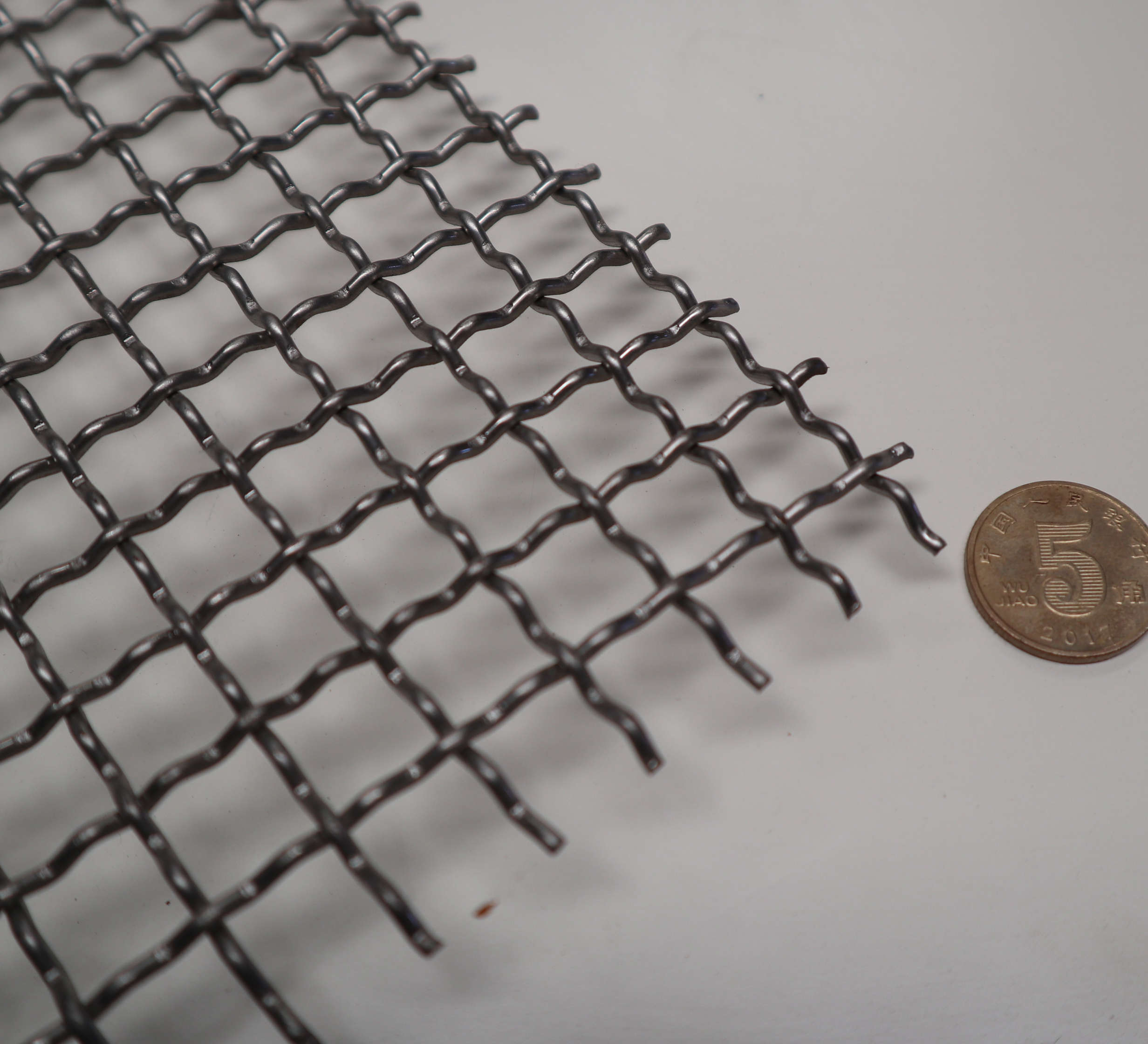

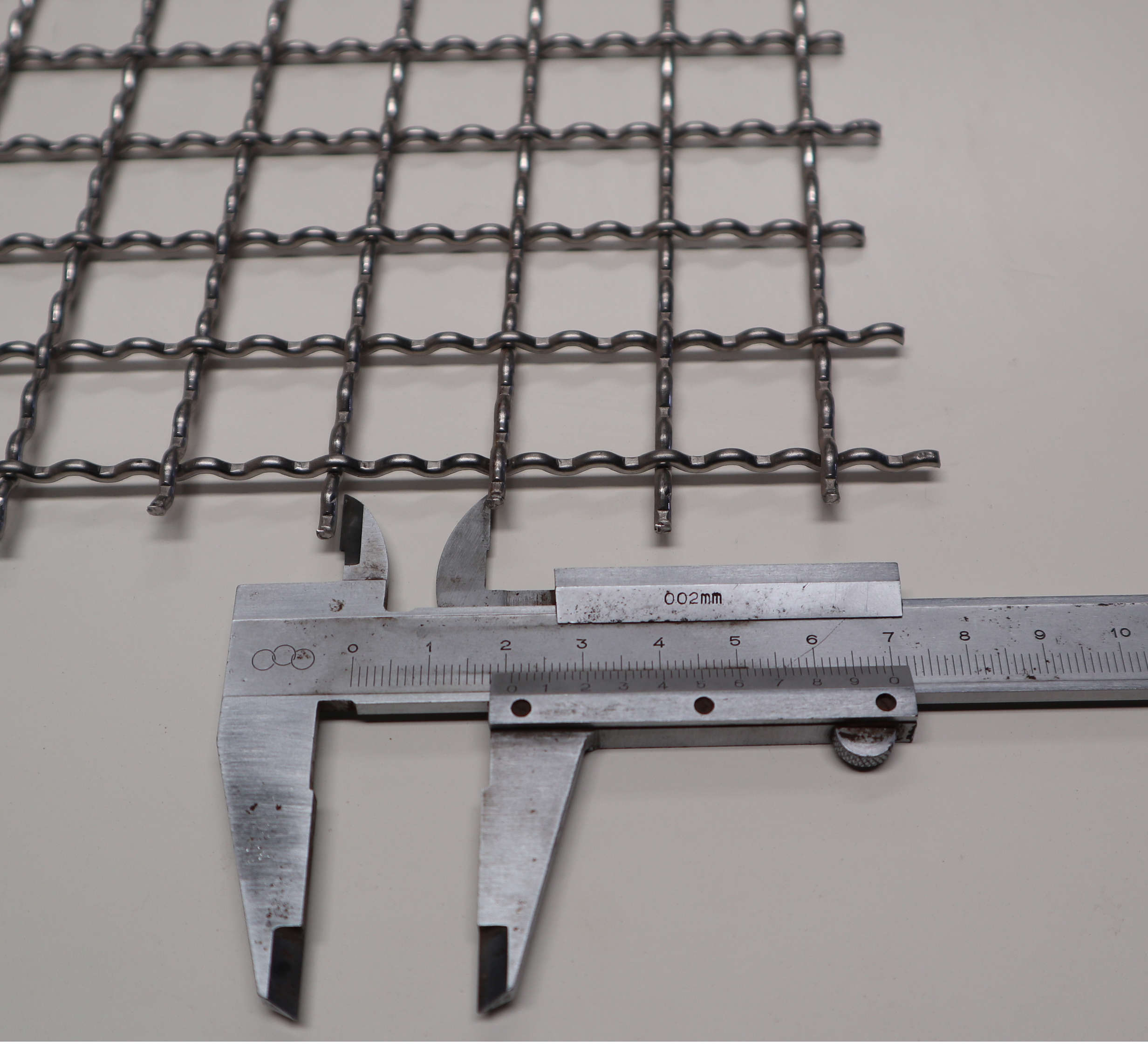

Crimped wire mesh is constructed of wires that have been crimped prior to weaving them together in a loom. Crimping the wires before weaving provides stability and consistency in larger spaced wire mesh. Various crimping styles have been developed over the years to improve manufacturing efficiencies, function, and aesthetics. The most common materials used to create Cripmed wire mesh are 65Mn steel wire, galvanized steel, stainless steel, aluminum, Brass and Copper..

Features of Crimped Wire Mesh

- Solid construction

- Extremely versatile

- East to install

- Can have low resistance to wind loads

- Easily cut to fit

- Available in many materials, such as stainless steel and aluminum

- Stainless steel cripmed wire mesh is especially useful because it is extremely chemical resistant, works with hot or cold liquids, and is easily cleaned. Aluminum mesh is lightweight, strong, has a high electrical conductivity, and a low melting point. Aluminum mesh also significantly resists atmospheric corrosion. Carbon steel and galvanized wire mesh are strong, economical, and readily available. Other exotic materials such as copper and nickel can also be woven into wire mesh.

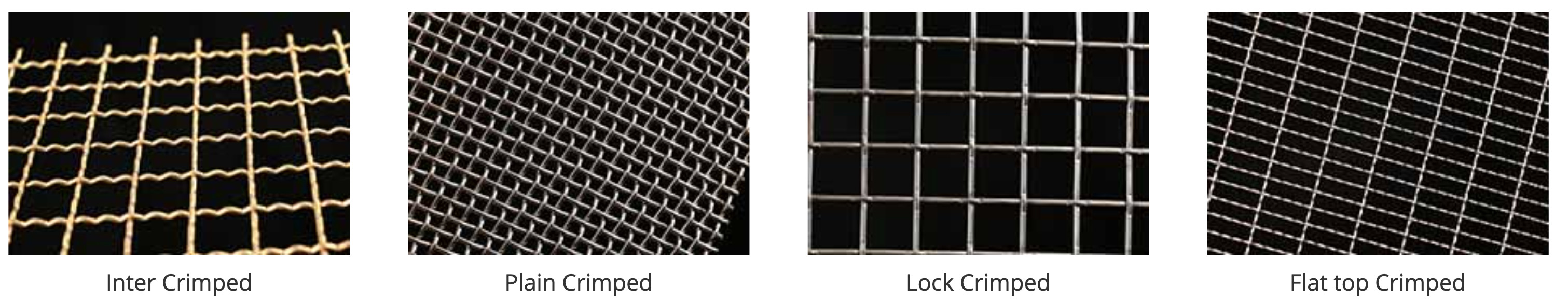

Weave Type

| Wire Gauge (SWG) |

Wire Diameter (mm) |

Mesh/Inch |

Aperture (mm) |

Weight (kg/m2 ) |

| 6 |

4.8 |

0.7 |

3 |

14 |

| 6 |

4.8 |

1 |

2 |

20 |

| 6 |

4.8 |

1.2 |

2 |

20 |

| 8 |

4.05 |

18 |

1 |

15 |

| 14 |

2 |

5.08 |

0.3 |

12 |

| 14 |

2 |

2.1 |

1 |

2.5 |

| 14 |

2 |

3.6 |

1.5 |

1.9 |

| 14 |

2 |

21 |

1 |

4.2 |

| 19 |

1 |

2.3 |

0.18 |

1.45 |

| 22 |

0.71 |

12 |

0.14 |

2.94 |

| 23 |

0.61 |

18 |

0.8 |

3.4 |

| 24 |

0.55 |

16 |

0.1 |

2.5 |

| 24 |

0.55 |

14 |

0.12 |

4 |

| 25 |

0.5 |

20 |

0.61 |

2.6 |

Application

| • Fencing |

• Baskets |

• Grills |

| • Grates |

• Display shelves and stands |

• Racks |

| • Liquid filtration |

• Air filtration |

• Wall reinforcement |