DESCRIPTION

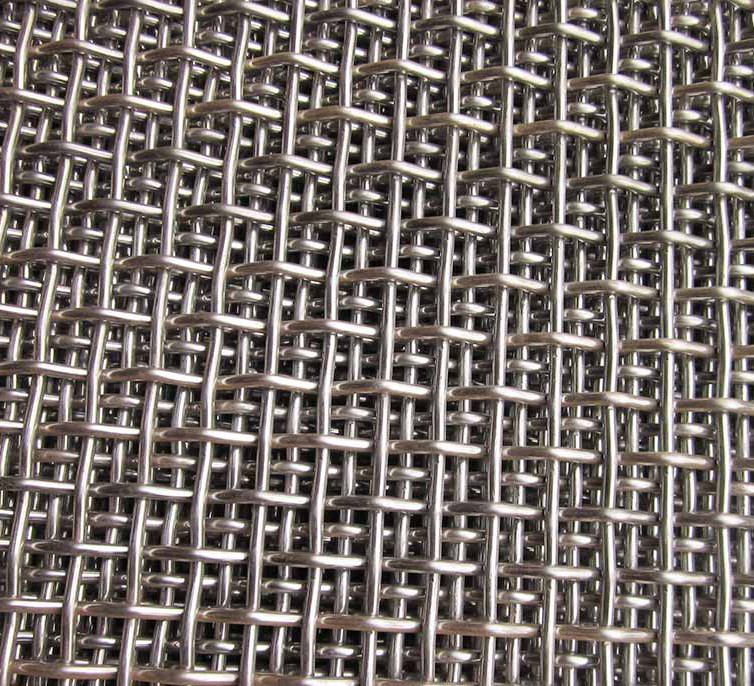

Quarry screen mesh Feature:

- High Tensile Woven Wire Mesh Aperture: 1.6 mm to 150 mm

- Woven Wire Thickness: 1.2 mm – 13 mm

- Mesh Types: Square Mesh, Rectangular Slotted Mesh and Elongated Mesh

- Crimp Types: Flat Top, Double Crimp, Lock Crimp, Corrugated Crimp

Heavy Duty Crimped Wire Mesh Material is High tensile steel wire, 45# steel wire, 65Mn steel wire. It is used in are always used in mine, coal industry for sieving the stone and sand. mesh panels with different edge. 65Mn is the most common material of the manganese steel quarry screen mesh.

MESH TYPES of Quarry screen mesh

Rectangular Slotted Mesh is economical to manufacture, and has a greater open area for increased air flow where binding or clogging occurs. The variable slot lengths mean it is often used to reduce flake content of material to acceptable levels.

Extra Long Slotted Mesh is manufactured with double or triple cross wires. It is stronger and more cost effective in comparison to Piano Wire or Self-Cleaning Screens. It provides a high open area and higher throughput than normal slotted mesh, decreasing the risk of clogging or binding.

Square Mesh is the most cost efficient of the Woven Mesh range with an expanded lifespan. The formation of the wire allows for screening and production of regular shaped material. Square Mesh decreases the risk of clogging.

SELF CLEANING SCREENS are recommended where the prevention of clogging and anti-pegging are required, or in very difficult areas. Crimped and straight wires are connected by cross wires at regular intervals. The wires vibrate independently of each other.

Application of Quarry screen mesh

Quarry Screen mesh is widely used in vibrating screen machines to filter and separate sands, gravel, coal, stones, rocks and other wet and dry materials.

-

Sand and gravel industry

-

Vibrating screen machines

-

Mining industry

-

Crusher

-

Quarry

-

Trommel